Diesel Catalytic Converters Technical Information

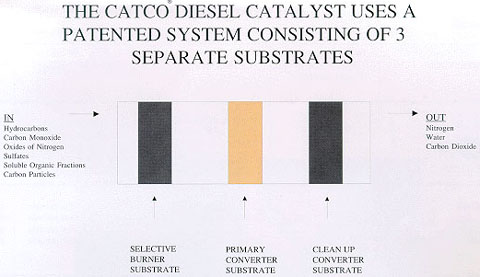

The

Selective Burner Substrate starts the process by the selective burning of larger

particulates. This burning also helps start the catalytic reduction

process of NOX as well as CO and HC conversion in the Primary Converter.

The Primary

Converter continues the NOX, HC, and CO reduction and conversion and aids in the

light off of the Clean Up Converter substrate.

The Clean Up

Converter substrate finishes any reduction and conversion that still needs to be

done as well as finishing the Particulate Matter reduction.

The Special

Silica Carbide substrate lights off faster, retains heat longer and by virtue of

its flow characteristics, helps to reduce NOX and Particulates.

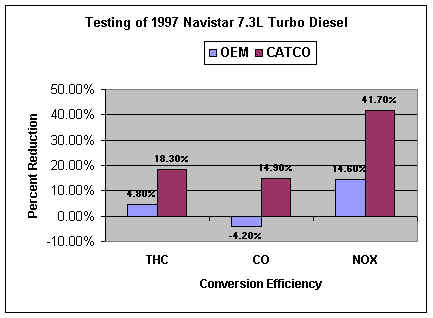

Following are Examples of the Excellent Emission

Reductions Performed by Catco Diesel Catalysts

|

Engine Type

|

Reduction by Percentage

|

|

CO

|

HC

|

NOX

|

PM

|

|

Isuzu 90 HP

|

86%

|

86%

|

30%

|

60%

|

|

Isuzu 210 HP

|

93%

|

91%

|

16%

|

<70%

|

|

Mack E7-400

|

No Test

|

No Test

|

No Test

|

<60%

|

|

Perkins 4.236

|

87%

|

81%

|

No Test

|

<50%

|

| International DT466

(Eng. Built Early 1980's)

|

No Test

|

No Test

|

No Test

|

<60%

|

| Cummins 855 290 HP

(Eng. Built Early 1980's)

|

No Test

|

No Test

|

No Test

|

<80%

|

|

ImageBuilders

ImageBuilders